#modular robotics market

Explore tagged Tumblr posts

Text

The global modular robotics market is projected to grow from USD 12.69 billion in 2024 to over USD 66.42 billion by 2034, driven by advancements in automation technologies and widespread industry adoption.

0 notes

Text

How are Modular Robotics Systems Revolutionizing Factory Operations?

The ballooning utilization of collaborative modular robotics systems is one of the biggest factors responsible for the expansion of the global modular robotics market. Cobots, as they are popularly called, are revolutionizing robot and human relationships in the logistics and manufacturing industries. These systems allow operators to directly provide parts and components to robots for performing the rest of the operation, which leads to reduced requirement for floor space, lower costs, and shorter process time.

Additionally, the highly versatile nature of these systems allows them to perform various tasks and operations with the help of several suitable end-effectors. In the logistics industry, cobots are used for inspecting fragile goods and transporting loads and machine parts. Because of these reasons, the sales of collaborative modular robotics systems are rising rapidly across the world. Besides this, the growing requirement for automation in the manufacturing industry is also fueling the demand for these robots around the world.

Due to the aforementioned factors, the modular robotics market is growing rapidly all over the world. The valuation of the market is predicted to rise from $5.6 billion to $15.1 billion from 2019 to 2030. Furthermore, the market is expected to progress at a CAGR of 9.9% between 2020 and 2030. Depending on robot type, the market is categorized into cartesian modular robots, articulated modular robotics systems, SCARA modular robotics systems, parallel modular robots, and collaborative modular robots.

Out of these, the articulated modular robotics systems category recorded the highest growth in the market in the past years and this trend is likely to continue in the coming years as well. This would be due to the large-scale usage of these robots for handling and managing heavy automotive components and parts in the automotive industry. In addition to this, these robots are extensively used for handling heavy metal parts and sheets in the metal and machinery industry.

The growing sales of these robots are boosting the demand for services, software, and hardware. Out of these, the demand for hardware will be the highest in the future, as per the forecast of the market research company, P&S Intelligence. Sensors, manipulators, driver modules, and controllers are the most commonly used types of hardware. Amongst these, the usage of controllers is currently the highest, because of the utilization of robot controllers in various industrial robots for accomplishing point-to-point repetitive tasks.

Geographically, the modular robotics market registered the highest growth in the Asia-Pacific (APAC) region in the years gone by. This was because of the huge investments that were made in automation in electricals, electronics, and automotive industries, particularly in countries such as India, China, and South Korea. In addition to this, the high usage of collaborative modular robotics systems by various manufacturers further propelled the advancement of the market in the region in the past.

Hence, it can be said with full surety that the sales of modular robotics systems would shoot-up all over the world in the forthcoming years, mainly because of the rising requirement for automation in various industries such as automotive, logistics, electricals, and electronics and also, in the manufacturing sector.

Source: P&S Intelligence

#Modular Robotics Market Share#Modular Robotics Market Size#Modular Robotics Market Growth#Modular Robotics Market Applications#Modular Robotics Market Trends

1 note

·

View note

Text

Wake up, babe. New Robot Lord just dropped!

If you're in the market for amazing looking 3D prints for your generic undead robot needs, look up NAPKING on MyMiniFactory. This comes from a modular kit that makes AMAZING Robot Lords.

#miniature painting#warhammer 40k#wh40k#necrons#one page rules#portfolio#3d printing#robot lord#Robot Legions

71 notes

·

View notes

Note

(Want to put this one out for public) What would you say is the most impressive action figure you've personally bought?

"Impressive" is a tough word considering the… let's be charitable and say "significant" number of figures I've collected over many, many years.

I have many I consider beautiful, or iconic representations of characters I love, but that's not the same thing, though there is heavy overlap as I tend to only buy figures of characters I like.

I have even been gifted with some extraordinary unique ones, in the form of unreleased versions, or custome mad figures by incredibly talented people.

But you didn't ask for "Favourite" or "Most valuable", you asked for "Impressive" and even then I can only narrow it down to a few

I own an original G1 Transformers Japanese box set of the Predacons. (It was more of a complicated international (three continent) swap between different fandoms, but I did the co-ordinating, and money was involved in getting this as my end result)

This one isn't mine, but it's the same set

The individual beast modes look great, their individual robot modes are cool and Predaking himself is freaking awesome.

It might be cheating as it's not a single figure, its a combiner but it was SOLD as the combined figure so I'm loopholing it in! :P

The Figma Table Museum series is amazing, with action figure representations of figures from art and history, including DaVinci's Vitruvian Man, Botticelli's Birth of Venus, Michelangelo's David, Munsch's The Scream and Rodin's Thinker amongst others

But my favourite is their Tutankhamun, which has a staggering level of detail. The regular version has the mummy with a beautiful sculpt of the famous death mask. The DX version includes one of the sarcophagi that the mummy was found in, which the figure fits inside and, again, the sculpting is remarkable.

Plus a random shout out to Figma's other figures, which are never less than impressive

And I would be remiss if I didn't include at least one of the Saint Seiya Myth Cloths (So, I'm going to include two).

Andromeda Shun is one of my all time favourite characters, and the figures they have created for him are stunning, especially once the geeks who grew up on the roginal anime grew up and started working on making action figures themselves

This is what the original mass market 1987 figure for Shun looked like which, I should add in case I seem churlish, I remain inordinately fond of.

This is what the 2010 Myth Cloth looked like

Bit of a glow up, isn't it! :) (Pricewise too, but that's neither here nor there)

And the Gold Libra Saint remains a remarkable creation, the representational form of a pair of weighing scales transforming nicely into not only the Cloth itself, but the six pairs of weapons it contains, one for each of the Gold Saints

Honourable mention to several of NECA's lines, like Gargoyles and Fraggle Rock, which are impressive sculpts

Oh, and a shoutout out for sheer mechanical creativity goes to the BeastBox series from 52Toys. The main gimmick being that each figure, no matter how large or complex, unfolds from a standard modular 1.5" cube shape

I only have a few of them, because I suspect I could get VERY hooked on these, but these include White Noise, the owl (looking like Bubo from Clash of the Titans got an upgrade)

and Ironblood and Loyalheart, the twin battle bunnies who share a cube between them

However, I suspect I will surprise no one in that perhaps the one that continues to impress me each and every time I see it is one related to another characterI am forever associated with.

Which is of course, Robin, the Boy Wonder!

This is the Hot Toys Batman 1966 version, which is a superb 11" figure generally (allowing for some of the ever present issues with fabrics on smaller figures, meaning his cape is rather over-stitched so it's not too fragile)

But it's the face sculpt which gets me every time, this is way beyond the uncanny valley and right into the downright eeriely lifelike (And no surprise there, Hot Toys are legendary for their likenesses)

THIS is a plastic sculpt and paint job? They've even given him freaking FRECKLES!! (He probably has nose hair too, though I admit I've never checked for that... I'm weird, but not THAT flavour of weird)

Though, me being me, you might also not be surprised that I am also fond of the sculpting on this other Hot Toys Robin, though in that case, it's not just the face ;) !

20 notes

·

View notes

Link

#AgriTechSolutions#CrossSectorInnovation#DisasterResponseSystems#IndustrialDrones#PrecisionMechatronics#QuantumResilientTech#SupplyChainResilience#TriangularManufacturing

0 notes

Text

Steel Slag Equipment Market transformation through automation and environmental innovations

The steel slag equipment market is undergoing a major transformation fueled by two dominant forces: automation and environmental innovations. As steel manufacturers face rising regulatory scrutiny and growing sustainability demands, their investment focus is rapidly shifting toward advanced slag processing solutions that optimize recovery, reduce emissions, and increase energy efficiency.

Steel slag, once regarded as a mere industrial waste byproduct, is now being revalued for its applications in road base materials, cement blends, construction aggregates, and metal recovery. This shift from waste to resource is accelerating technological advancement in slag equipment, particularly with the integration of smart technologies that align with green metallurgy principles. Governments and industries alike are pushing for solutions that reduce landfilling, improve resource circularity, and meet emissions targets.

The role of automation in this evolution cannot be overstated. Modern steel slag equipment is now commonly embedded with intelligent control systems and digital sensors. These additions help operators monitor performance metrics in real-time, optimize throughput, and conduct predictive maintenance to avoid costly downtimes. Earlier, slag handling and cooling were largely manual or semi-automated processes. Today, full automation — from hot slag transportation and granulation to crushing and magnetic separation — is a key differentiator among leading equipment providers. With artificial intelligence, machine learning, and robotics increasingly embedded into core machinery, automation is no longer a luxury but a competitive necessity.

Environmental regulations are simultaneously pushing the steel sector to clean up its footprint. Equipment manufacturers are now engineering slag crushers, separators, and granulators that consume less power, emit lower noise, and operate with minimal dust release. For example, energy-efficient induction systems are replacing traditional combustion-based processes, while water reuse systems are being integrated into granulation units to reduce wastewater discharge. Additionally, enclosed slag cooling solutions have emerged to replace open-air cooling, which previously led to particulate emissions and unsafe working conditions. These innovations reflect a market-wide alignment with environmental, social, and governance (ESG) imperatives.

Moreover, the integration of digital twin technology is starting to gain traction in the steel slag equipment market. This innovation allows operators to create a virtual replica of the entire slag processing plant, simulate various load conditions, and optimize design parameters before actual deployment. It enhances fault prediction, supports remote monitoring, and ensures continuous improvement. Such solutions are particularly valuable in large-scale facilities processing thousands of tons of slag daily, where efficiency, uptime, and recovery rates significantly affect profitability.

Another area of innovation lies in the development of modular and mobile slag processing units. In response to spatial limitations and fluctuating volumes in smaller steel plants, equipment makers are offering compact systems that can be quickly deployed, relocated, or scaled. These modular units not only reduce installation time and upfront capital expenditures but also provide flexibility to adjust to regional capacity or temporary surges in slag generation.

Sustainability demands have also catalyzed the push toward closed-loop slag systems. These systems focus on capturing and reusing not just the solid slag, but also thermal energy and exhaust gases. Some systems now offer heat recovery modules that channel thermal output into auxiliary plant heating systems or electricity generation, thereby improving overall plant energy performance. Others incorporate advanced magnetic separators capable of extracting multiple metal fractions, increasing the material's post-processing value while reducing raw material dependency.

Global steel-producing hubs such as China, India, and parts of Europe are leading the shift. In these regions, government incentives, stricter emissions regulations, and a rising emphasis on green steel production are encouraging facilities to upgrade existing slag systems. For instance, the European Green Deal and China's Five-Year Plans have provisions that incentivize advanced resource recovery and cleaner industrial technologies. Equipment makers with a proactive innovation agenda are capitalizing on these frameworks to expand their geographic footprint.

Partnerships between slag equipment providers and steel manufacturers are also gaining importance. Many large-scale steel firms are no longer buying off-the-shelf equipment but are instead entering co-development arrangements with OEMs to tailor equipment to their specific slag chemistry, plant layout, and process integration needs. Such collaborations yield higher ROI for buyers and help suppliers refine their technology offerings through real-world feedback.

The ongoing decarbonization wave across the steel sector is projected to further accelerate demand for eco-efficient equipment. Electric arc furnaces (EAF), which generate different slag compositions compared to blast furnaces, are increasingly becoming the norm in developed markets. This transition is creating opportunities for manufacturers to introduce specialized EAF-compatible slag handling technologies. Equipment tailored for high-phosphorus or alloy-rich slag is also in demand as specialty steelmaking gains momentum globally.

In terms of challenges, high capital intensity remains a barrier for smaller players, especially in developing countries where return on investment is a critical concern. However, the emergence of equipment leasing models and government subsidies for cleaner technologies is gradually mitigating these hurdles. Digital training programs and remote commissioning services have also made technology adoption more feasible, even for low-resource facilities.

Looking ahead, the steel slag equipment market is poised to grow steadily, not just in volume but also in value, due to the rising preference for premium, integrated systems. The long-term outlook favors manufacturers that can balance cost-effectiveness with technological sophistication and environmental stewardship.

In conclusion, the steel slag equipment market is undergoing a profound transformation, shaped by the twin forces of automation and environmental innovation. These trends are not temporary; they represent a systemic shift in how steel byproducts are managed and monetized. Companies that invest in smarter, cleaner, and more agile equipment solutions today are likely to lead the market tomorrow.

#SteelSlagEquipment#EnvironmentalInnovation#SmartManufacturing#GreenSteel#MetallurgyTech#SteelRecycling#AutomationInIndustry#SustainableSteel#IndustrialTransformation#SteelIndustryTech#ProcessOptimization#ZeroWasteSteel

0 notes

Text

Rugged Embedded System Market Experiences Surge Amid Rising Adoption in Transportation and Defense Sectors

The rugged embedded system market has emerged as a pivotal segment in the global embedded technology landscape. These systems are engineered to operate reliably in harsh environments where standard commercial-grade systems would fail. Applications range from military and aerospace to industrial automation, transportation, marine, and energy sectors—driving steady demand and innovation.

What are Rugged Embedded Systems?

Rugged embedded systems are specialized computing devices built to withstand extreme temperatures, vibrations, moisture, dust, and electromagnetic interference. Unlike consumer-grade electronics, they are designed for durability, long lifecycle performance, and uninterrupted operation in mission-critical scenarios. Typically, these systems include industrial-grade processors, solid-state drives, fanless enclosures, and are compliant with industry standards such as MIL-STD-810G, IP67, and EN50155.

Market Drivers

One of the most significant drivers of the rugged embedded system market is the growing demand for automation and smart technologies across industries. In manufacturing, rugged systems control robotic arms and industrial machinery, enabling predictive maintenance and real-time monitoring. In defense, they are integrated into surveillance equipment, drones, and battlefield communication tools, ensuring reliable data processing in combat zones.

Transportation also plays a critical role. With the rise in smart transportation and intelligent traffic systems, rugged embedded computers are essential in railways, metro networks, and autonomous vehicles. They enable tasks such as signal control, navigation, communication, and safety system management.

The rise of the Internet of Things (IoT) has further propelled the market. Edge computing devices in remote or outdoor locations, such as oil rigs or weather monitoring stations, rely heavily on rugged systems to process and transmit data efficiently without centralized servers.

Regional Landscape

North America holds a dominant share in the rugged embedded system market, largely due to its advanced defense industry and high adoption of industrial automation. The U.S. Department of Defense’s consistent investment in advanced electronics for unmanned systems and battlefield management continues to fuel demand.

Europe is also a significant player, particularly in railways and energy. Countries like Germany, France, and the UK are investing in smart infrastructure and green energy, where rugged systems monitor and optimize performance.

Meanwhile, the Asia-Pacific region is expected to witness the fastest growth. The rapid industrialization of India, China, and Southeast Asia, combined with increasing defense budgets and infrastructure development, presents massive opportunities for rugged embedded technology.

Key Challenges

Despite its growth, the rugged embedded system market faces challenges. High development and testing costs can limit the entry of new players. Moreover, the long design cycles and strict compliance requirements pose barriers to innovation. System integration is also complex, especially in legacy environments where interoperability and backward compatibility are essential.

Cybersecurity is another pressing issue. As rugged systems become more connected, they are vulnerable to cyber threats. Ensuring secure communication protocols and firmware integrity is critical to maintaining operational resilience.

Future Trends

The future of the rugged embedded system market is tied closely to advancements in artificial intelligence (AI), 5G, and edge computing. AI-integrated rugged systems can enable real-time decision-making in remote environments, enhancing efficiency and responsiveness. The deployment of private 5G networks in industrial zones will allow faster, more reliable communication among devices.

Another trend is modularity. Manufacturers are focusing on developing flexible, modular systems that allow for upgrades and scalability without full hardware replacement—an essential feature for long-term cost-efficiency and adaptability.

Sustainability is becoming a design priority. Environmentally friendly materials and energy-efficient components are increasingly used to meet global sustainability standards and reduce the carbon footprint.

Competitive Landscape

Leading players in the rugged embedded system market include Kontron, Advantech, Curtiss-Wright, Crystal Group, and Eurotech. These companies invest heavily in R&D and collaborate with OEMs to develop customized solutions across industries. Strategic partnerships, mergers, and geographic expansions are common tactics to gain market share.

Conclusion

The rugged embedded system market is poised for robust growth as industries increasingly depend on reliable, durable, and intelligent systems to perform in the harshest conditions. With expanding applications, ongoing technological innovations, and rising global demand, the sector offers vast opportunities for manufacturers and developers. However, navigating the challenges of cost, complexity, and cybersecurity will be essential for sustained success.

0 notes

Text

U.S. ERP Software Market Growth Potential for the Period 2025 to 2032 | At a CAGR of 3.6%

The U.S. Enterprise Resource Planning (ERP) software market size was valued at USD 12.84 billion in 2024, and it is projected to grow from USD 13.29 billion in 2025 to USD 16.99 billion by 2032, registering a CAGR of 3.6% during the forecast period. While growth is moderate, market dynamics are shifting due to increasing demand for integrated platforms, cloud ERP deployment, and regulatory compliance needs across industries.

Key Market Highlights:

2024 Market Size (U.S.): USD 12.84 billion

2025 Market Size (U.S.): USD 13.29 billion

2032 Market Size (U.S.): USD 16.99 billion

CAGR (2025–2032): 3.6%

Market Outlook: Stable growth supported by manufacturing digitization, financial process automation, and cloud migration

Top ERP Vendors in the U.S. Market:

SAP America

Oracle Corporation

Microsoft (Dynamics 365)

Workday

Infor

Epicor Software

Sage Group

Acumatica

Unit4

IFS

Plex Systems

NetSuite (Oracle)

Request for Free Sample PDF: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/u-s-enterprise-resource-planning-erp-software-market-107427

Market Dynamics:

Key Growth Drivers:

Demand for Real-Time Operational Visibility: Organizations increasingly rely on centralized ERP platforms to consolidate finance, inventory, HR, and supply chain data.

Cloud-First IT Transformation: Adoption of cloud-based ERP solutions is accelerating among SMBs and large enterprises for improved scalability and cost-efficiency.

Compliance and Audit Readiness: ERP systems are instrumental in maintaining SOX compliance and audit trails for public and private firms.

Integration with Emerging Tech: ERP platforms are being enhanced with AI, machine learning, and robotic process automation (RPA) for smarter business operations.

Manufacturing Sector Revamp: U.S.-based manufacturers are adopting ERP to support smart factories, procurement digitization, and resource optimization.

Key Opportunities:

AI-Enhanced ERP Modules: Use of AI for demand forecasting, predictive maintenance, and anomaly detection in operations

ERP for Services Sector: Rapid expansion of ERP adoption in healthcare, legal, and professional services for project accounting and compliance

Mid-Market Expansion: Growing availability of modular, affordable ERP offerings for mid-sized U.S. firms

Vertical-Specific ERP: Tailored ERP systems for construction, education, manufacturing, and logistics industries

Mobile and Edge ERP Solutions: Expanding need for mobile-first and field-accessible ERP dashboards

Technology & Application Landscape:

Deployment Models:

Cloud ERP (SaaS)

On-Premises ERP

Hybrid ERP

Key ERP Modules:

Financial Management

Human Capital Management (HCM)

Inventory & Supply Chain Management

Manufacturing & Production

CRM & Order Management

Business Intelligence & Reporting

End Users:

Manufacturing

Retail

Healthcare

Education

Construction

Public Sector

Speak to Analysts: https://www.fortunebusinessinsights.com/enquiry/speak-to-analyst/u-s-enterprise-resource-planning-erp-software-market-107427

Recent Developments:

February 2024 – Oracle introduced new GenAI-powered features in Oracle Fusion Cloud ERP for U.S. enterprises, enhancing real-time decision-making and scenario modeling.

July 2023 – SAP launched its Green Ledger initiative within SAP S/4HANA Cloud to help American enterprises track carbon emissions as part of their ERP reporting.

September 2023 – Workday extended its ERP offering for mid-sized U.S. companies with tailored HCM and finance tools, offering a low-code configuration engine.

Trends Shaping the U.S. ERP Market:

AI and Predictive Analytics: ERP systems integrating ML algorithms for forecasting demand, sales, and workforce needs

Composable ERP: Rise of microservices and modular ERP architectures that let organizations customize solutions based on evolving needs

Cybersecurity Integration: Emphasis on data security, access control, and compliance built into ERP layers

IoT and Edge Connectivity: ERP platforms are increasingly linking with smart devices and edge hardware in logistics and manufacturing

User-Centric Interfaces: Simplified dashboards, voice-enabled commands, and mobile app expansion

Conclusion:

Though the U.S. ERP software market is experiencing steady, moderate growth, the market remains strategically important as enterprises look to digitally transform core business operations. The future of ERP in the U.S. is cloud-first, intelligent, and composable, offering agility, compliance, and performance across verticals. As legacy systems are phased out, ERP vendors that offer modular, AI-powered, and industry-specific solutions will lead the next wave of enterprise efficiency.

Frequently Asked Questions:

1. What is the projected value of the global market by 2032?

2. What was the total market value in 2024?

3. What is the expected compound annual growth rate (CAGR) for the market during the forecast period of 2025 to 2032?

4. Which industry segment dominated market in 2023?

5. Who are the major companies?

6. Which region held the largest market share in 2023?

#U.S. Enterprise Resource Planning Software Market Share#U.S. Enterprise Resource Planning Software Market Size#U.S. Enterprise Resource Planning Software Market Industry#U.S. Enterprise Resource Planning Software Market Analysis#U.S. Enterprise Resource Planning Software Market Driver#U.S. Enterprise Resource Planning Software Market Research#U.S. Enterprise Resource Planning Software Market Growth

0 notes

Text

How Robotics Labs Are Shaping the Future of Education in India

In recent years, the educational landscape in India has undergone significant changes. No longer confined to blackboards and textbooks, classrooms are now embracing digital tools to create immersive, hands-on learning environments. Among the most transformative of these tools are robotics labs—spaces where students can imagine, build, and innovate.

Robotics labs are not just about building machines; they represent a shift toward experiential learning. By combining science, technology, engineering, and mathematics (STEM) with creativity and problem-solving, these labs prepare students for a world where digital skills are as essential as literacy.

The Growth of Robotics in Indian Schools

India’s education system is catching up fast with global trends in technology. With government policies like the National Education Policy (NEP) 2020 emphasizing skill-based learning, more schools are investing in STEM infrastructure to bridge the gap between theory and practice. One key component of this shift is the Robotics Lab setup in school, which allows students to work on real-time projects, understand programming logic, and develop critical thinking skills.

These labs are not limited to elite institutions. Many progressive CBSE and state board schools across metro cities and small towns are now integrating robotics into their curriculum. From primary to senior secondary levels, students are being exposed to hands-on tech experiences that spark curiosity and foster innovation.

A New Way to Learn and Think

In a robotics lab, learning becomes more than memorization. Students write code, assemble mechanical parts, and solve design problems, all while working in teams. Whether they’re programming a robot to follow a path or designing a prototype to complete a task, they are actively engaged in learning by doing.

Introducing a Robotics lab in your school can significantly boost student motivation and classroom participation. Concepts that once seemed abstract—like sensors, automation, or artificial intelligence—become real and understandable. Even students who typically struggle in traditional academic settings often excel when they have the chance to learn through building and experimentation.

Robotics also promotes resilience. When a robot doesn’t function as expected, students learn to troubleshoot and improve it, developing persistence and confidence along the way.

Building Future-Ready Skills

Beyond technical knowledge, robotics helps students gain essential life skills such as collaboration, creativity, and communication. As they brainstorm ideas, divide responsibilities, and present their results, they learn how to work effectively with others and express themselves clearly.

In today’s fast-changing job market, these “soft skills” are just as critical as technical ones. A well-rounded Robotics lab for schools ensures that students are not only coding and constructing machines, but also developing the human skills needed to thrive in future workplaces.

Many schools also encourage participation in robotics competitions, science fairs, and innovation challenges, allowing students to test their skills in real-world scenarios and build portfolios that stand out in higher education admissions.

Expanding Access Beyond Big Cities

What makes robotics education particularly exciting in India is its growing reach. Thanks to government support, NGO initiatives, and private sector partnerships, robotics is no longer limited to urban schools. Tier 2 and Tier 3 cities, and even some rural schools, are now exploring cost-effective robotics programs.

Simple kits, modular curricula, and teacher training are making it easier to bring robotics to every corner of the country. These labs are helping level the playing field by giving all students—regardless of background—access to future-focused learning.

Empowering Teachers and Curriculum Integration

For robotics labs to succeed, teachers need support too. Schools must invest in training educators so they feel confident using robotics tools and guiding students through projects. With the right resources, teachers become facilitators who encourage exploration, rather than just deliver content.

Robotics doesn't have to be limited to a single subject either. It can enhance learning across disciplines—bringing math, physics, computer science, and even art into a shared space of creativity and application.

When integrated thoughtfully, robotics labs can transform how schools teach and how students learn.

The Path Ahead

Despite the clear benefits, challenges remain. Some schools face budget constraints or lack access to skilled trainers. However, with increasing awareness and available support, these barriers are gradually being overcome. Schools that start with small pilot programs and grow from there are finding it easier to manage costs and scale impact over time.

The journey is just beginning, but the direction is clear: robotics will play a major role in the future of Indian education.

Conclusion: A Smart Investment in Young Minds

Robotics labs are shaping a generation of learners who are not afraid to question, explore, and create. In India, where the potential for innovation is vast, these labs are helping young minds dream bigger—and build the tools to turn those dreams into reality.

Whether your school is located in a major city or a small town, integrating robotics into the classroom opens up new opportunities for teaching, learning, and growing. It’s not just about keeping up with the future—it’s about leading the way there.

0 notes

Text

Top Insights from Exploring the Impact of Robotics on Modern Manufacturing

Manufacturing is undergoing a profound shift, one where automation and intelligent systems are rewriting traditional production models. At the heart of this transformation lies robotics. Exploring the impact of robotics on modern manufacturing reveals not just improvements in output and accuracy but also deep changes in workforce dynamics, operational agility, and global competitiveness. Robotics is no longer just a cost-cutting tool—it is a strategic lever for innovation and sustainability.

The Evolution of Robotics in Manufacturing From the assembly lines of the 20th century to today’s smart factories, robotics has evolved from mechanical repetition to sophisticated autonomy. Early robotic arms performed singular tasks, but today’s robots are agile, adaptable, and connected to cloud-based intelligence. The integration of AI, machine vision, and predictive analytics allows modern robots to learn, optimize, and respond in real time, opening the door to mass customization and operational flexibility.

Robotic Automation and Production Efficiency One of the most significant contributions of robotics is the increase in speed and throughput. Robots handle repetitive tasks with unwavering consistency, allowing human workers to focus on supervision, analysis, and innovation. By minimizing downtime and eliminating errors, robotic automation enhances cycle times and streamlines workflows. This shift is crucial in meeting global demand without compromising quality.

Quality Control and Precision Engineering Consistency is the hallmark of robotic systems. In high-precision sectors such as electronics, automotive, and aerospace, robotics ensures microscopic accuracy and repeatability that human labor alone cannot guarantee. Integrated vision systems and sensors enable real-time monitoring and defect detection. This has not only reduced waste and rework but has elevated the overall reliability of production systems.

Workforce Transformation and Human-Robot Collaboration Contrary to fears of job displacement, robotics is redefining roles rather than replacing them. The focus is shifting toward collaboration, where robots perform strenuous tasks while humans handle decision-making and maintenance. This symbiosis improves workplace safety, reduces fatigue, and opens new opportunities for upskilling. As robotic systems grow more intuitive, the future workplace will rely on human-robot teams working side by side.

Supply Chain Resilience Through Robotic Integration Disruptions over the last few years have emphasized the need for agile, responsive manufacturing systems. Robotics plays a vital role in enabling just-in-time operations and localized production. Automated warehousing, robotic sorting, and predictive logistics powered by AI allow manufacturers to manage inventory better, reduce lead times, and improve responsiveness to market shifts.

Robotics and Sustainable Manufacturing Energy-efficient robotics and resource-optimized automation are supporting the industry’s shift toward sustainability. Robotic systems reduce material waste, optimize energy usage, and ensure precision in raw material handling. Additionally, by enabling closed-loop manufacturing models and recycling processes, robotics supports circular economy principles. Manufacturers are increasingly leveraging robots not just for efficiency but also to meet ESG goals.

Challenges and Considerations in Robotics Adoption While the benefits are clear, implementation requires thoughtful planning. Upfront investment, training needs, cybersecurity concerns, and system interoperability remain common challenges. However, as costs decline and modular, scalable robotics become more accessible, even small and mid-sized manufacturers are finding paths to adoption. A strategic approach ensures that robotics enhances rather than disrupts core operations.

For More Info https://bi-journal.com/exploring-the-impact-of-robotics-on-modern-manufacturing/

Conclusion Exploring the impact of robotics on modern manufacturing shows that automation is more than a technological upgrade—it is a blueprint for resilience, competitiveness, and innovation. Robotics empowers manufacturers to scale sustainably, adapt to changing demands, and create smarter, safer work environments. The integration of robotics represents not the end of the traditional manufacturing workforce, but the beginning of a new era where machines enhance human potential and drive forward the future of industry.

#Smart Manufacturing#Industrial Automation#Robotics In Manufacturing#BI Journal#BI Journal news#Business Insights articles

0 notes

Text

0 notes

Text

Trends and Forecasts in the Second Life Industrial Robot Market

The Second Life Industrial Robot MarketSecond Life Industrial Robot Market is rapidly expanding as businesses increasingly seek cost-effective automation solutions across manufacturing, logistics, and automotive sectors. These pre-owned, refurbished robots offer a budget-friendly alternative to new systems while delivering reliable performance and extended lifecycles. Growing trends include advanced refurbishing services, AI integration, and alignment with Industry 4.0 technologies, enhancing robot adaptability and efficiency. Despite challenges like standardization gaps, compatibility issues, and skilled labor shortages, the market benefits from rising demand driven by cost optimization and sustainability efforts. With ongoing innovations and a focus on circular economy practices, the second-life robot market is poised for significant growth and greater adoption worldwide.

Market Segmentation:

1. By End Use:

Industrial

Waste Recycling

Others

2. By Type of Refurbishment:

New Controller Technology

Others

3. By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Players

ABB

FANUC

IRS Robotics

Key Demand Drivers

Inexpensive Automation for Small and Medium Businesses: Because second-life robots drastically lower startup costs, automation is now affordable for manufacturers on a budget as well as small and mid-sized businesses (SMEs). This affordability is especially alluring in budget-conscious competitive industries and growing markets.

Goals for the Circular Economy and Sustainability: Businesses are adopting sustainable practices as a result of increased environmental awareness and more stringent e-waste rules. In line with circular economy concepts, refurbished robots prolong the useful life of current gear while lowering the load on landfills and conserving vital resources.

Improvements in Technology: Refurbished robots are becoming more versatile thanks to improved controller systems, AI integration, and machine learning applications. These improvements make older models more useful in high-precision settings and smart factories by enabling them to function on par with machines of the latest generation.

Market Challenges

Absence of Standardized Procedures for Renovation: Variations in robot safety, dependability, and quality caused by inconsistent refurbishing procedures among vendors may worry end users and restrict further adoption.

Integration Difficulties: Connecting legacy systems to automation platforms, Industry 4.0 frameworks, or contemporary software environments may necessitate extensive adaptation. Potential customers may be turned off by these integration fees, which can cancel out any initial savings.

Lack of Skilled Workers: Industrial robot maintenance and repair require specialized technical knowledge. The consistency of refurbished equipment quality and the scalability of services can be affected by a shortage of qualified personnel.

Get your hands on this Sample Report to stay up-to-date on the latest developments in the Second Life Industrial Robot Market.

Gain deep information on Robotics and Automation Market. Click Here!

Future Outlook

Through 2030, the market for used industrial robots is anticipated to develop significantly due to the combined demands of sustainability and economic efficiency. The performance of reconditioned robots will continue to improve with the development of AI-enabled control systems and modular modifications, making them more and more feasible for high-end industrial applications. With the help of favorable government policies, growing SME automation, and fast industrialization, the Asia-Pacific area is expected to grow at the fastest rate. Because of its well-established robotics infrastructure and advanced refurbishing skills, North America is expected to continue to hold its dominant position.

Conclusion

With its perfect blend of cost, sustainability, and performance, the second life industrial robot market is becoming a vital part of the worldwide automation scene. Refurbished robots are turning out to be a valuable asset for contemporary industry as the need for intelligent, environmentally friendly, and scalable automation solutions increases. Even if there are still issues with standardization and integration today, industry cooperation, technical advancement, and training programs should help to lessen them over time. The market for second-life robots is positioned for long-term growth and change because to strong regional demand and growing environmental concern.

#Second Life Industrial Robot Market#Second Life Industrial Robot Industry#Second Life Industrial Robot Report#robotics#automation

0 notes

Text

Tail-Wagging Innovation: The Rise of the Pet Bed Industry

In a world where pets are cherished as beloved family members, their comfort has become a priority for many households. Among the many accessories pampered pets enjoy, the humble pet bed has evolved into an essential item that blends functionality, comfort, and even fashion. At the heart of this transformation lies the modern pet bed factory—a hive of creativity, precision, and dedication to furry well-being.Get more news about pet bed factory,you can vist our website!

A typical day in a pet bed factory begins with raw materials. High-quality fabrics, memory foam, recycled polyester fills, and even orthopedic-grade materials arrive at the loading bays. Sustainability is no longer a luxury in this industry—it’s an expectation. Many factories now source eco-friendly or recycled materials to reduce environmental impact, appealing to increasingly conscientious pet owners.

Once materials are cataloged and inspected, the process transitions to the cutting stage. Automated machines equipped with laser precision carve out fabric patterns based on computer-aided designs. These designs consider everything from the size of the pet to the desired style, whether it’s a plush donut-style cushion or a sleek, modern orthopedic mat.

After cutting, it’s time to stitch. Highly trained seamstresses—or increasingly, robotic arms with surgical accuracy—assemble the beds with detailed stitching to ensure durability and safety. For round beds, patterns are sewn into a spiral to maintain shape. For orthopedic beds, layers of foam are carefully bonded and encased. Every seam is a promise: that the bed will withstand daily wear and tear from paws, claws, and teeth.

Quality control is a critical phase in the production line. Each bed is tested for resilience, comfort, and cleanliness. Zippers, seams, and fillers are inspected rigorously. Even aesthetic details, like fabric patterns or logo placement, are carefully reviewed. Some factories even employ scent testing to ensure the final product is odor-free and welcoming for sensitive pet noses.

But innovation doesn’t stop at production. Leading pet bed factories often operate R&D labs to test new designs—like temperature-regulating fabrics, waterproof linings, or customizable modular beds that grow with the pet. There’s a shift toward personalization, allowing pet parents to order monogrammed beds or choose colors that complement their home décor. For luxury brands, limited-edition collections in collaboration with designers are becoming common, further blurring the line between pet products and fashion.

The global pet bed market is booming, with increasing demand from both developed and emerging markets. E-commerce platforms have made it easier for niche brands and factory-direct suppliers to reach consumers worldwide. Many factories now offer dropshipping models or custom branding solutions for retailers looking to build their own pet product lines.

Behind the scenes, a pet bed factory is more than a place of manufacturing—it’s a blend of engineering, textile craftsmanship, and love for animals. Each finished product represents hours of thoughtful design and dedication, destined to become the cozy haven where pets curl up after a long day of play.

So next time you see a contented cat lounging or a dog snoring on a comfy cushion, just remember: that peaceful slumber was made possible by the skilled hands and smart machines of a pet bed factory.

0 notes

Text

Automation and Integration Needs Power Robust Growth in System Integrator Market

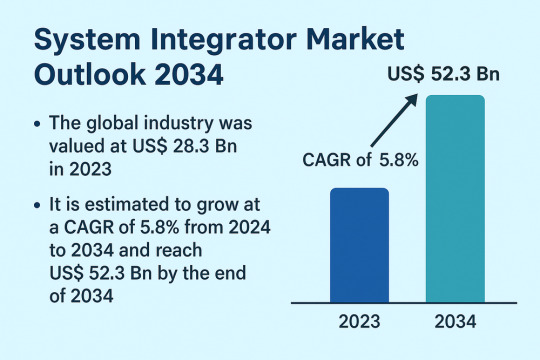

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Vertical Farming Market to Hit $13.7 Billion by 2029 Driven by AI and Sustainability

The Vertical Farming Market is poised for exponential growth, forecasted to increase from approximately USD 5.6 billion in 2024 to USD 13.7 billion by 2029, growing at a compound annual growth rate (CAGR) of 19.7%. This transformation is being driven by urbanization, increasing food demand, water scarcity, and technological innovations including artificial intelligence (AI), LED lighting, and hydroponic systems.

To Get Free Sample Report: https://www.datamintelligence.com/download-sample/vertical-farming-market

Market Drivers and Growth Opportunities

Scarcity of Arable Land and Water Vertical farming systems require up to 97% less water and significantly less land than traditional farming, making them ideal for densely populated cities and regions suffering from water scarcity.

Integration of AI and Automation AI is revolutionizing vertical farming by enabling predictive analytics, automation of nutrient delivery, environmental control, and yield optimization. Coupled with IoT and sensors, farms can operate efficiently with minimal human input.

Year-Round Production and Urban Scalability Controlled environment agriculture allows year-round production regardless of climate conditions. This is especially crucial in urban areas where local food production can reduce dependency on external supply chains and transportation.

Rising Demand for Clean, Pesticide-Free Produce Health-conscious consumers are driving demand for fresh, pesticide-free food. Vertical farming offers a solution with clean growing environments that eliminate the need for chemical treatments.

Government Incentives and Policy Support Supportive policies in both developed and developing countries are fostering investment and research in sustainable agricultural practices, including vertical farming.

U.S. Market Insights

The United States is one of the leading adopters of vertical farming technology. In urban food deserts regions with limited access to fresh food small and modular farms are addressing local needs. For example, projects in cities like Houston, Phoenix, and Mesa are creating access to greens using hydroponics and aeroponics.

Energy use remains a major challenge, as climate-controlled farms consume high levels of electricity. However, innovators are mitigating this through renewable energy integration and partnerships with local energy providers. Furthermore, advanced LED lighting is being optimized for energy efficiency.

Despite some high-profile vertical farm companies declaring bankruptcy due to overexpansion or unprofitable scale, many small and mid-size operators are succeeding with localized, efficient models. Companies like Bowery Farming are providing produce to major retailers including Walmart and Whole Foods, supported by automation and AI tools that streamline farm management.

Startups like True Garden are demonstrating profitability with container-based models, producing thousands of pounds of greens each month while using 90–98% less water than traditional farms.

Japan Market Trends

Japan’s vertical farming industry is expanding rapidly, driven by the need for domestic food production and sustainability. Indoor farms, known as "vegetable factories," are increasingly integrated into urban environments. The vertical farming market in Japan was valued at USD 402 million in 2024 and is projected to reach USD 879 million by 2033, with a CAGR of 9.1%.

Robotics, biosciences, and AI are at the core of Japan's vertical farming technology. Companies like Spread are leveraging cloud-based farm management systems to distribute greens to thousands of retail stores. The cultural alignment with sustainability, minimal waste, and urban efficiency positions Japan as a key global influencer in vertical farming.

Government funding and corporate investment are further accelerating growth, particularly in the development of fully automated farming systems that reduce reliance on human labor.

Global Market Landscape

The Asia-Pacific region, beyond Japan, is also witnessing notable growth. In 2023, the market was valued at USD 1.77 billion and is projected to reach USD 7.04 billion by 2030 at a CAGR of 21.8%. Countries such as Singapore, South Korea, and China are investing heavily in vertical farming for urban food security.

Hydroponics is currently the dominant method due to its water efficiency and scalability. Aeroponics is gaining momentum, especially in Japan and parts of Europe, due to its superior nutrient delivery and root oxygenation.

Investment Opportunities

Vertical farming is attracting venture capital across multiple fronts:

Automation and AI: Investors are prioritizing platforms that use AI to manage farm ecosystems in real-time.

Container and Modular Farms: Scalable, transportable farms offer a solution for urban redevelopment and rural supply gaps.

Premium Crop Segments: High-value crops like microgreens, strawberries, and herbs offer better margins for vertical farmers.

Food Security Projects: Urban governments and non-profits are partnering with startups to launch vertical farms in underserved neighborhoods.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/vertical-farming-market

Industry Challenges

High Energy and Infrastructure Costs Energy-intensive systems for lighting, heating, and environmental control present cost challenges. Co-locating farms with renewable energy sources is a potential solution.

Scalability and Profitability Balance Large-scale operations often struggle with profitability, whereas smaller localized farms show better financial performance and community impact.

Supply Chain and Distribution Ensuring freshness and shelf life, especially for leafy greens, requires efficient local distribution networks.

Conclusion

The vertical farming market is on a transformative path. Innovations in AI, hydroponics, and sustainable lighting are enabling farms to flourish in environments previously unsuitable for agriculture. While energy consumption and initial investment remain hurdles, the long-term benefits of local food production, water savings, and food security are positioning vertical farming as a central player in the future of agriculture. With leadership from the U.S. and Japan, and rapid growth in the Asia-Pacific region, vertical farming is no longer experimental it is becoming essential.

0 notes

Text

Pedicle Screw Systems Market : Size, Trends, and Growth Analysis 2032

The Pedicle Screw Systems Market was valued at US$ 1,998.90 million in 2024 and is projected to grow at a CAGR of 5.90% from 2025 to 2032. The increasing global burden of spinal disorders, coupled with advances in minimally invasive surgical technologies, is fueling the demand for robust spinal fixation systems. Among these, pedicle screw systems have become the cornerstone of spinal fusion and deformity correction procedures, offering unmatched structural support and surgical outcomes.

What Are Pedicle Screw Systems?

Pedicle screw systems are specialized orthopedic implants used in spinal stabilization procedures, particularly spinal fusion surgeries. These systems consist of screws that are inserted into the pedicles — the cylindrical bony projections off the back of each vertebra. Once secured, the screws are connected using rods, hooks, or plates to form a rigid frame that stabilizes the spine, allowing vertebrae to fuse together over time.

This system is designed to limit movement in the affected spinal segment, thereby promoting healing and reducing pain caused by spinal instability, deformities, or degenerative conditions.

Key Market Drivers

1. Rising Incidence of Spinal Disorders

Conditions such as scoliosis, spinal stenosis, spondylolisthesis, herniated discs, and traumatic spinal injuries are on the rise due to aging populations, sedentary lifestyles, and increased road traffic accidents. These disorders often necessitate surgical intervention involving pedicle screw systems to restore spinal alignment and stability.

2. Growth in Minimally Invasive Spine Surgery (MISS)

Minimally invasive techniques are revolutionizing spinal surgeries by offering reduced recovery times, less blood loss, and smaller incisions. Many modern pedicle screw systems are specifically designed for MISS, allowing surgeons to perform precise screw placement under fluoroscopic or robotic guidance.

3. Technological Advancements in Implant Design

Manufacturers are innovating with biocompatible materials (like titanium and PEEK), improved thread designs, and cannulated screws for percutaneous placement. Customizable and modular systems are also gaining traction, allowing surgeons greater flexibility in addressing patient-specific anatomical challenges.

4. Increased Surgical Volumes Worldwide

With greater access to healthcare and rising awareness of surgical solutions for chronic back pain, both elective and trauma-related spinal surgeries are increasing globally. This directly boosts demand for pedicle screw systems as standard-of-care instrumentation in spine stabilization.

5. Robotics and Navigation Technology Integration

The integration of robot-assisted surgical platforms and 3D navigation systems has elevated the accuracy of pedicle screw placement. These technologies reduce the risk of neurological damage and post-operative complications, further enhancing the appeal of pedicle screw-based surgeries.

Application Segmentation

Degenerative Disc Disease: A common cause of lower back pain, often requiring fusion to restore disc height and eliminate motion between vertebrae.

Spinal Trauma and Fractures: Pedicle screws provide immediate stabilization in cases of vertebral fractures due to accidents or falls.

Scoliosis and Spinal Deformities: Used to correct and maintain spinal alignment in congenital, idiopathic, or neuromuscular scoliosis cases.

Spinal Tumors and Infections: When surgical excision leads to destabilization, pedicle screws help support the remaining spinal structure.

Revision Surgeries: In cases where previous surgeries have failed, robust fixation systems like pedicle screws are often re-employed.

Product Insights

Monoaxial Pedicle Screws: Offer rigid fixation, used in deformity correction when high stability is required.

Polyaxial Pedicle Screws: Allow multidirectional movement, preferred in procedures requiring anatomical alignment flexibility.

Cannulated Screws: Enable percutaneous insertion, ideal for minimally invasive surgeries.

Expandable Screws: Designed to increase anchorage in patients with osteoporotic bone, improving fixation in the elderly.

Regional Analysis

North America

Holds the largest share due to high surgical volumes, rapid adoption of novel technologies, and strong presence of market leaders. The U.S. leads in spine surgery rates, supported by advanced hospital infrastructure.

Europe

Second-largest market driven by growing aging populations, especially in countries like Germany, France, and the UK. Reimbursement support and a skilled healthcare workforce boost market growth.

Asia-Pacific

Fastest-growing region owing to increasing healthcare access, rising spinal disorder prevalence, and a surge in medical tourism, particularly in countries like India, China, and South Korea.

Latin America & Middle East and Africa (MEA)

Emerging markets where investment in healthcare infrastructure and growing awareness about surgical treatment options are expanding the scope for pedicle screw system adoption.

Key Market Players

Medtronic PLC

A global leader in spinal implants, Medtronic offers a comprehensive suite of pedicle screw systems under its Spinal & Biologics division, with a focus on minimally invasive and robotic-compatible technologies.

DePuy Synthes (Johnson & Johnson)

Offers advanced spinal fixation systems known for modularity and ease of use, supported by the company’s global distribution network and surgeon training programs.

Stryker Corporation

Renowned for innovative product designs and integration with its MAKO robotic platform, enhancing precision in screw placement and surgical outcomes.

Zimmer Biomet

Delivers spinal hardware systems with a focus on patient-centric solutions, including expandable and MIS-friendly pedicle screw products.

Globus Medical Inc.

A strong innovator in spinal surgery technologies, Globus is investing in robotic guidance and next-gen pedicle screw platforms.

NuVasive Inc.

A pioneer in lateral spine surgery techniques, NuVasive develops highly specialized pedicle screw systems aligned with MISS protocols.

Orthofix Medical Inc.

Focused on fusion and non-fusion spinal solutions, Orthofix’s systems are often used in trauma, deformity, and complex spinal reconstruction cases.

Market Trends

Patient-Specific Implants: Custom 3D-printed pedicle screws and guides are being developed based on patient imaging data, increasing surgical accuracy and fit.

Osteoporotic Solutions: With aging demographics, there is a rising focus on screw designs that improve purchase in brittle bone, such as expandable and cement-augmented screws.

Sustainability and Biocompatibility: A shift toward recyclable, hypoallergenic materials and coatings that reduce inflammation and improve long-term outcomes.

Smart Implants: Future potential lies in sensor-embedded screws that monitor healing progress or implant stress post-operatively.

Browse more Report:

Instrumentation Sterilization Containers Market

Infectious Enteritis Treatment Market

High-Integrity Pressure Protection System Market

High Temperature Overhead Conductor Market

Flowable Hemostats Market

0 notes